| Tweet |

Custom Search

|

|

|

||

TM 9-8000

a. Driving Members. The driving members of a clutch

usually consist of two cast-iron plates or flat surfaces

machined and ground to a smooth finish. Cast iron is

recommended because it contains enough graphite to

provide some lubrication when the driving member is

slipping during engagement. One of these surfaces

usually is the rear face of the engine flywheel, and the

other is a heavy, flat ring with one side machined and

surfaced. This part is known as the pressure plate. It is

fitted into a steel cover, which also contains some of the

operating members, and is bolted to the flywheel.

b. Driven Members.

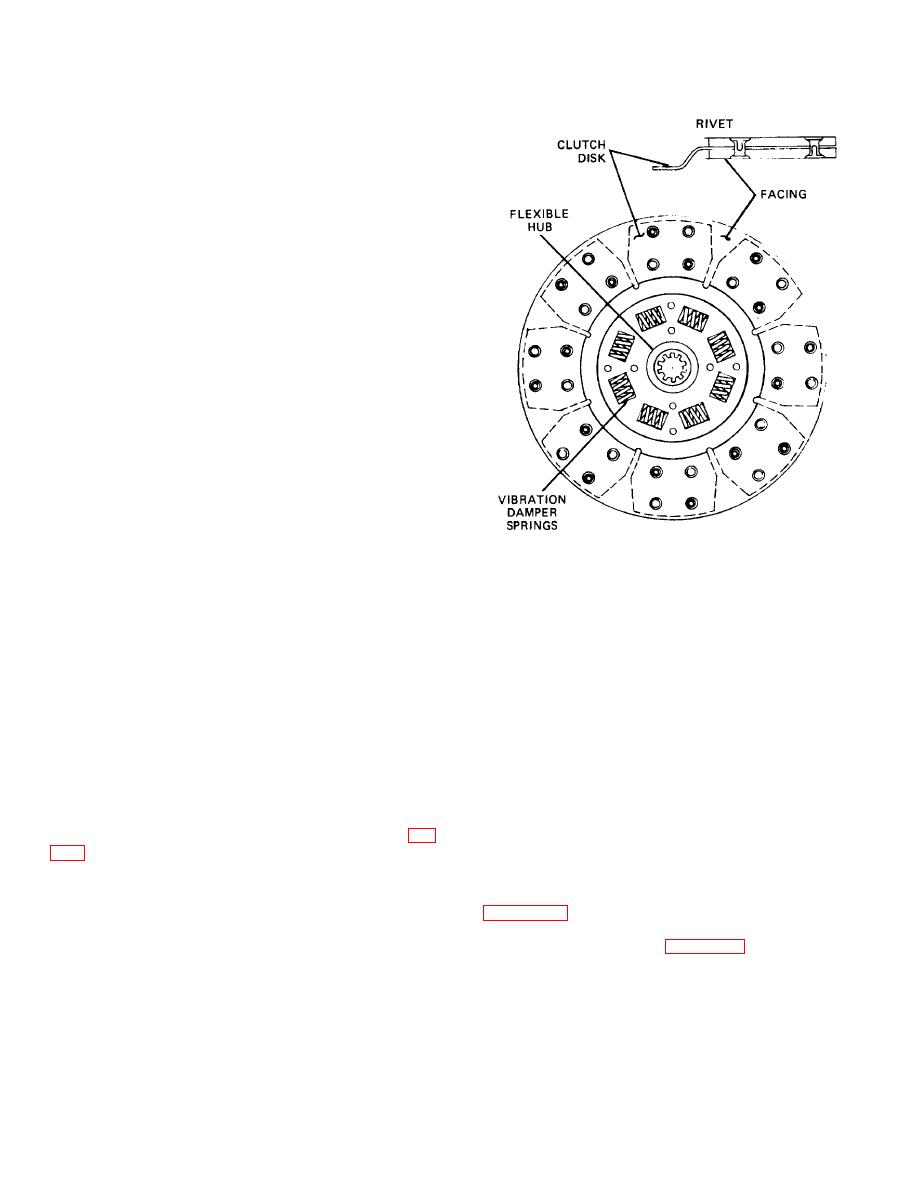

(1) The driven member is a disk with a splined hub that

is free to slide lengthwise along the splines of the clutch

shaft. These same splines also transmit torque from the

disk to the clutch shaft. (The driven member sometimes

is referred to as the clutch plate, but the word disk will be

used here to denote the driven member and thus

differentiate between this part and the clutch pressure

plate.) The clutch disk usually is made of spring steel in

the shape of a single flat disk of a number of flat

segments. Suitable frictional facings are attached to each

side of the disk by means of copper rivets. These facings

must be heat resistant because friction produces heat.

Figure 21-2. Clutch-Drive Plate with Flexible

The most commonly used facings are made of cotton

Center.

and asbestos fibers woven or molded together and

impregnated with resins or similar binding agents. Very

absorb the torsional vibration of the crankshaft, which

often, copper wires are woven or pressed into the

would be transmitted to the power train unless it were

material to give it additional strength.

eliminated. The flexible center usually takes the form of

steel compression springs placed between the hub and

(2) In order to make clutch engagement as smooth as

the steel disk. The springs permit the disk to rotate

possible and eliminate chatter, several methods have

slightly with relation to its hub until, under extreme

been used to give a little flexibility to the driven disk. One

conditions, the springs are compressed fully and relative

type of disk is dished, so that the inner and outer edges

motion stops. Then the disk can rotate slightly backward

of the friction facing make contact with the driving

as the springs decompress. This slight backward and

members first, and the rest of the facing makes contact

forward rotation permitted by the springs allows the

gradually as the spring pressure increases and the disk

clutch shaft to rotate at a more uniform rate than the

is flattened out. In another type, the steel segments

crankshaft, thereby eliminating some of the torsional

attached to the splined hub are twisted slightly, which

vibration from the crankshaft and preventing the vibration

also causes the facings to make gradual contact as the

from being carried back through the transmission.

disk flattens out. (3) The driven member of the clutch (fig.

c. Operating Members. The driving and driven members

are held in contact by spring pressure. This pressure

may be exerted by a single, large coil spring as shown in

located circumferentially around the outer portion of the

pressure plate as shown in figure 21-1;

or a one-piece conical or diaphragm spring as

TA233674

21-2

|

||

|

||