| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

CYLINDER VALVES AND ASSOCIATED PARTS REPAIR

THIS WORK PACKAGE COVERS:

Cleaning, Inspection, and Repair

INITIAL SETUP:

Tools and Special Tools:

Personnel Requirements:

General mechanic's tool kit (item 121, WP 0176)

Track Vehicle Repairer (1) 63H10

Outside micrometer caliper set

Equipment Conditions:

(item 17, WP 0176)

Cylinder assembly removed (WP 0133)

Spring resiliency tester (item 118, WP 0176)

Valves removed (WP 0135)

Expendable Materials:

Prussian blue paste (item 25, WP 0173)

CLEANING

1. See Work Package 0028 for General Cleaning Procedures.

INSPECTION

All parts must be inspected with care.

Replace parts if damage or wear exceeds

allowable limits.

1. See Work Package 0028 for General

Inspection Procedures.

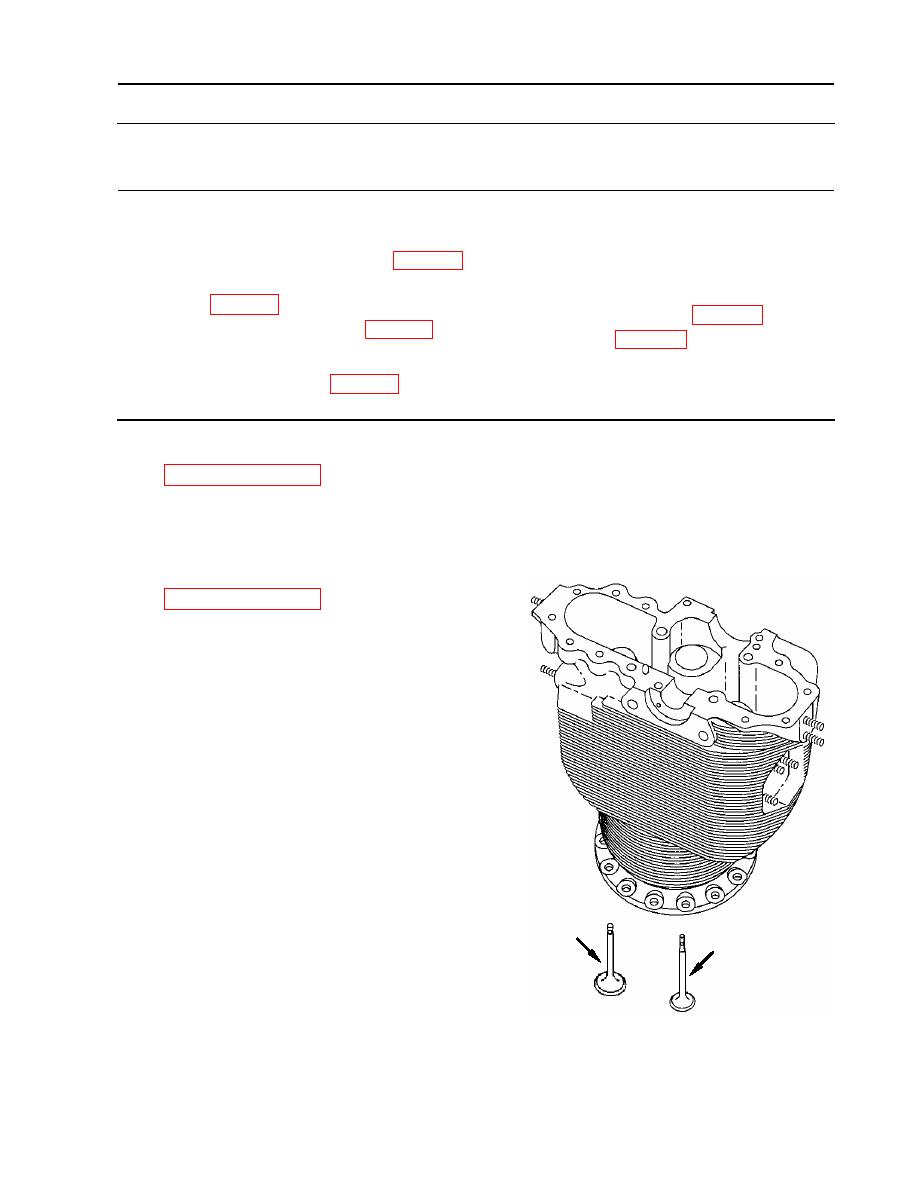

2. Inspect exhaust (1) and intake (2) valves for

evidence of pitting, imperfect seating, cracks,

or warping of valve head. Replace damaged

valves.

NOTE

Heavy discoloration, burning,

erosion, or heavy carbon deposit

on valve face indicates a warped

valve. A light frosted appearance

or minor discoloration on valve

face does not indicate a warped or

unserviceable valve.

3. Inspect exhaust (1) and intake (2) valve

2

stems and the locking groove in the stems for

1

pitting, scoring, cracks, or damaged ends.

Replace valves if damage is found.

WP 0145 00-1

|

||

|

||